Khan Thompsons StudIEAust Portfolio

My Portfolio

Welcome to my portfolio, here you’ll find a selection of my work. Explore my project's to learn more about what I do. All the below projects have been REPQ approved.

Steel Rack Project

What:

Designed and implemented a space-efficient, safe storage solution for metal sheets in the workshop. Save workshop floor sapce for cost savings.

How:

Utilized 3D CAD modelling, technical drawing creation, and FEA simulations; collaborated with tradespeople and local suppliers; and applied innovative solutions to technical challenges, notably in simulation and stress management.

Why:

To increase available floor space, while creating a more organised, safe and efficient workshop. Consiquently, leading to cost savings of

over $40,000, compared to off-the-shelf offerings.

Mustang Dynamometer Trailer

What:

Reverse-engineered and implemented cowlings for Australia's first light vehicle trailer dynamometer.

Created testing procedures for the trailer dynamometer to adhere to Vehicle Standards Bulletin 14 (VSB 14).

How:

Utilized Project management tool, Microsoft Project, to define initial scoping, timeline estimation and resource allocation.

Used 3D CAD to reverse engineer the cowlings from 3D models provided by the client.

Revised Vehicle Standards Bulletin 14 (VSB 14) to develop testing procedures.

Mustang Dynamometer Trailer Procedure Development

What:

Develop procedures to produce reports that will specify the vehicle Standards Bulletin 14 (VSB 14).

How:

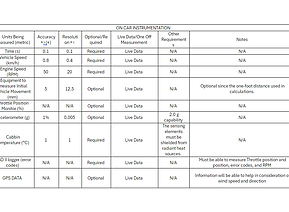

Set up procedure development for testing and calculations. Testing procedures developed for testing were developed to satisfy Australian standards. Risk analysis was conducted for the safety aspects of testing. Required instrumentation was determined from relevant standards.

Why:

To be able to offer reating of Trailer Weight Rating (TWR) allowing clients to tow more.

Control Arm Rating

What:

Undertaken analysis of the upper control arm system, for Toyota 200 Series family of vehicles.

Engineering to a Maximum Front Gross Axle Weight Rating (GAWR) of 2000kg, in accordance with the requirements of VSB 14.

How:

Leveraging 3D CAD modelling, I adeptly modified stress concentrations and conducted FEA simulations to enhance structural integrity. Bringing inventive strategies to the table, I excelled in addressing technical challenges, notably in simulation and effective stress management solutions.

Why:

Allowed the client to be able to sell upper control arms for the Toyota 200 Series family of vehicles, rated at 2000kg Maximum Front Gross Axle Weight Rating (GAWR).

Tray Mount AS1664 Analysis

What:

Conduct Finite Element Analysis for Ranger Extra Cab (EC), Dmax Extra Cab, Single Cab (SC), and Hilux Extra Cab (EC) tray mounts using AS1664 and various payloads.

How:

After modifying the original design to be simulated, I then calculated the loads following the Australian standards.

Additionally, I used FEA to verify the design and used hand calculations to support the simulation.

Why:

Allowed the client to sell various tray mount upgrades that are rated at AS1664 load cases.

Large Fleet: Tray

What:

Designed and implemented a Tray for single, double, and extra cab variants for a large Queensland energy company. Commissioned for over 5000 vehicles.

How:

Utilized 3D CAD modelling, technical drawing creation, and FEA simulations. LEAN Methodology was used to make the production process as efficient as possible.

Why:

To provide the client with a product that meets their requirements. In addition to this, it has allowed us to develop largescale manufacturing processes.

Large Fleet: Canopy

What:

Designed and implemented a Canopy for single, double, and extra cab variants for a large Queensland energy company. Commissioned for over 5000 vehicles.

How:

Utilized 3D CAD modelling, technical drawing creation, and FEA simulations. LEAN Methodology was used to make the production process as efficient as possible.

Why:

To provide the client with a product that meets their requirements. In addition to this, it has allowed us to develop largescale manufacturing processes.

Large Fleet: Various Box

What:

Designed and implemented: Battery Box (shown above), Type A Box, Type B Box, Type C Box and Type D box for single, double, and extra cab variants for a large Queensland energy company. Commissioned for over 5000 vehicles.

How:

Utilized 3D CAD modelling, technical drawing creation, and FEA simulations. LEAN Methodology was used to make the production process as efficient as possible.

Why:

To provide the client with a product that meets their requirements. In addition to this, it has allowed us to develop largescale manufacturing processes.

Toyota Land Cruiser Canopy

What:

Designed a canopy for client's range of Toyota Land Cruisers.

How:

After defining requirements, I used

3D modeling to create an initial concept for the canopy.

Following collaboration with the client, I incorporated folded sheet metal to reduce manufacturing time. Additionally, it allowed more consistent products..

Why:

To provide the client with a product that met their requirements and vision.

Rear Tail Light Pods

What:

Designed rear tail light pods to reduce manufacturing time, while keeping the desired aesthetic.

How:

Used FEA and technical drawings to generate deliverables. Consulted subject matter experts on implementing sheet metal components.,

Why:

The client required a new design to reduce manufacturing time while maintaining the desired aesthetic.